High-quality metrology for quality control in the measuring room, production, incoming goods and development.

Zahnradpumpen & Misch- und Dosiermaschinen mit höchster Genauigkeit für die Verarbeitung von Flüssigkeiten und Pasten.

Hochgenaue Kugelführungen für spielfreie Hub- und Drehbewegungen beim Einsatz im Maschinen- und Vorrichtungsbau.

Einsatzbereiche von Mahr Maschinen

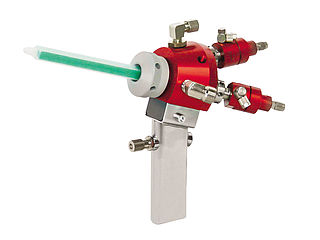

Proven use for decades to spin finest yarn: planetary spinning pumps are the heart of every synthetic fibre spinning plant.

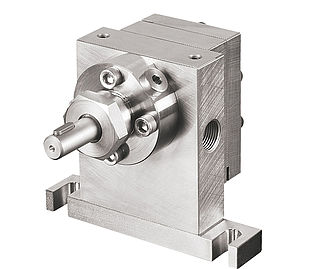

Spin finish dosing pumps do not only meter preparation fluids. They can also be used for the consistent dosing of water, perfume or even oils.

There are almost no limits to the use as a dosing pump in various industries. As a spinning pump it is only used for special applications.

Predominantly used in spinning and adhesives technology, they offer the possibility of realizing two flow rates with minimal space and one motor drive only.

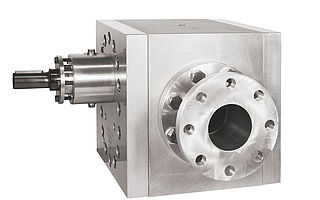

Product bores which are on both sides of the pump body allow the pump to be integrated directly into the production line.

They can be used for all applications. Direct installation in the product line does not require an additional clamping block.

Discharge pumps ensure gentle discharge of polymer melts with low product shear. Booster pumps ensure a defined process pressure for downstream tools such as dies or extruders.

For highly accurate, low-pulsation dosing of liquids. The gear metering pumps achieve an efficient performance even at low viscosity and back pressure.

Paint metering pumps can also be used for robot applications. Even at short flushing cycles these pumps show excellent flushing results.

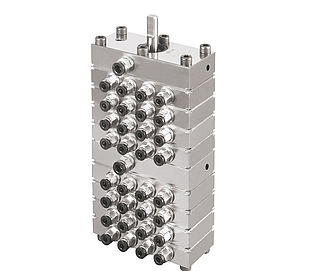

Solutions for material preparation, conditioning and supply to the meter mix dispense machine.

The mixing takes place exclusively through the flow movement of the components and the geometry of the mixing element.

The components are mixed by a rotating element in a mixing chamber.

The mixing takes place through the flow movement of the components in cooperation with the geometry and rotation of the mixing element.

MarDrum HV5Submersible Pump

HV5 High ViscositySubmersible Pump

Mahr Drum Metering Pumps are suitable for most precision metering of thin to thick viscosity products. Each system utilizes a gear metering pump which is force-fed by a special patented-design impeller, providing metering accuracy of ±1%. The impeller reduces the possibility of cavitation in the metering pump. The platen sits on the product surface riding down to the bottom of the barrel and can be heated. A rubber gasket on the outside of the platen completely cleans the sides of the container. Mahr Drum Pumps also prevent contamination of product by air, gas, and moisture.

- viscosities from up to 1,500,000 cP

- meters product to the bottom of the drum

- metering accuracy of ±1%

With a Mahr drum pump, no feed pump is necessary because it is mounted to pressurized the platen. This eliminates costly additional equipment. The drum metering pump is highly accurate with or without additional controls. Complete metering systems are available with recirculation loop, flow meter readout, PLC controls, data logging, touch screen interfaces and mixing systems.

| Emission range | 0.1 - 3.0 litres/min |

|---|---|

| Mixing ratio | Infinitely variable |

| Material tank sizes | 3 to 10 litres |

| Conveying element | Gear metering pump with stuffing box |

| Remote servicing | Remote service capability integrated |

| Tank filling | Manual |

| Operation via colour touch screen panel | Screen size 15" |

| Barrel | 5 gallon, 55 gallon, and custom drum sizes available (straight-sided drum required) |

| Max Temperature | 350 °C / 660 °F |

| Max Pressure | 5000 psi |

| Max Viscosity | (HV) 1 500 000 cP |

| Capacity (per stream) | 0.08 - 200 ml/rev |

| Speed | 10 - 80 rpm |

| Flow rate (per stream) | 0.8 - 16 000 ml/min |

Mass flow meters (Gear)

Pressure Transducer

Higher viscosity feed impeller

Special voltages

Motor control

Flow feedback control

Suitable for these applications:

Do you have questions about our products?

Please contact us at +49 (0) 2922-87840-0