Hochwertige Messtechnik für die Qualitätskontrolle in Messraum, Produktion, Wareneingang oder Entwicklung.

Zahnradpumpen & Misch- und Dosiermaschinen mit höchster Genauigkeit für die Verarbeitung von Flüssigkeiten und Pasten.

Hochgenaue Kugelführungen für spielfreie Hub- und Drehbewegungen beim Einsatz im Maschinen- und Vorrichtungsbau.

Einsatzbereiche von Mahr Maschinen

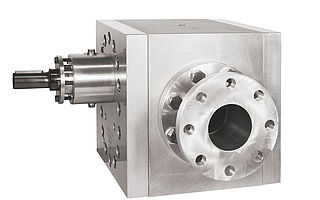

Proven use for decades to spin finest yarn: planetary spinning pumps are the heart of every synthetic fibre spinning plant.

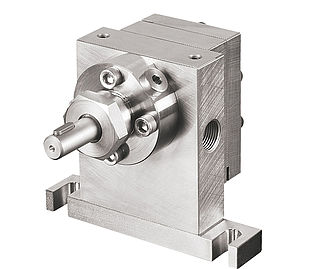

Spin finish dosing pumps do not only meter preparation fluids. They can also be used for the consistent dosing of water, perfume or even oils.

There are almost no limits to the use as a dosing pump in various industries. As a spinning pump it is only used for special applications.

Predominantly used in spinning and adhesives technology, they offer the possibility of realizing two flow rates with minimal space and one motor drive only.

Product bores which are on both sides of the pump body allow the pump to be integrated directly into the production line.

They can be used for all applications. Direct installation in the product line does not require an additional clamping block.

Discharge pumps ensure gentle discharge of polymer melts with low product shear. Booster pumps ensure a defined process pressure for downstream tools such as dies or extruders.

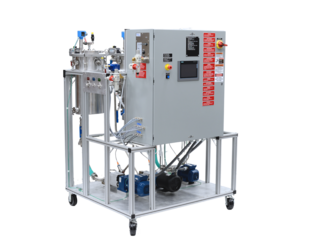

Gear pumps for the chemical industry, process pumps

Optimized metering pumps for chemical processes – low-pulsation gear pumps with high chemical resistance and precise metering

Paint metering pumps can also be used for robot applications. Even at short flushing cycles these pumps show excellent flushing results.

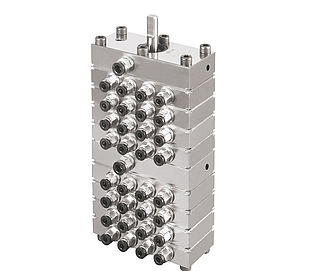

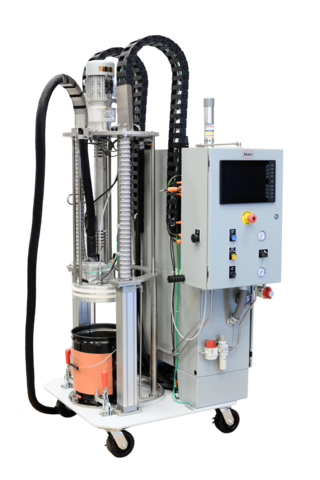

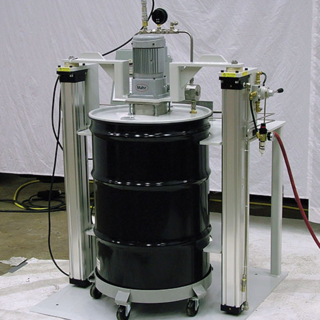

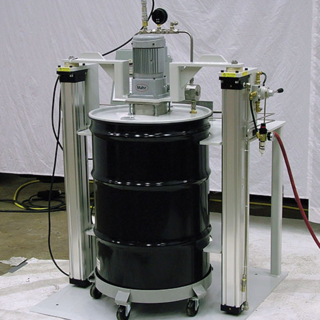

2part/3part mixing and dosing machine for small output quantities

Leistungsstark:

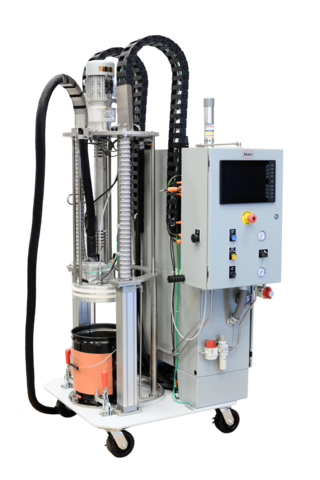

2K - nK Misch- und Dosiermaschine für hohe Ausstoßmengen.

2K - nK meter mix dispense machine for high material flow rates

2K - nK meter mix dispense machine for high material flow rates

The mixing takes place exclusively through the flow movement of the components and the geometry of the mixing element.

The components are mixed by a rotating element in a mixing chamber.

The mixing takes place through the flow movement of the components in cooperation with the geometry and rotation of the mixing element.

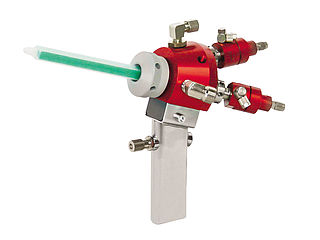

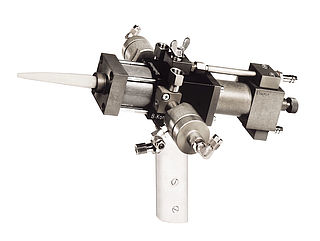

Spraying technique allows relatively quick and even distribution of reactive polymers systems such as epoxy resins and polyurethanes over large areas or complex contours and shapes. The applications range from thin coatings, such as the application of paint layers, adhesive and bonding agents/primers for metal-polyurethane bonding, also for coating of textile and in the production of artificial leather, up to thick layers application, as in polyurethane sprayed insulation in the construction sector. Spraying for combined applications between thin coating and subsequent thick foam in layer IMC process or addition of cut fibres in fibre spraying process are also possible.

The key factors in the spraying process are the correct and precise supply and coordination between spray air and resin quantities. Mix meter dispense systems from Mahr Unipre with their high meter mix dispense precision are predestined for spraying applications. Mixing heads and auxiliary accessories specially developed for spraying processes round up the product portfolio of Mahr Unipre for this demanding application.