Hochwertige Messtechnik für die Qualitätskontrolle in Messraum, Produktion, Wareneingang oder Entwicklung.

Zahnradpumpen & Misch- und Dosiermaschinen mit höchster Genauigkeit für die Verarbeitung von Flüssigkeiten und Pasten.

Hochgenaue Kugelführungen für spielfreie Hub- und Drehbewegungen beim Einsatz im Maschinen- und Vorrichtungsbau.

Einsatzbereiche von Mahr Maschinen

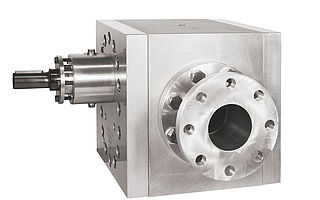

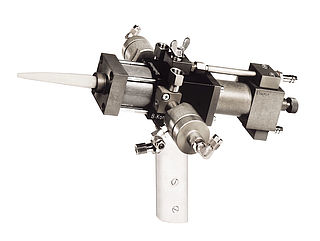

Proven use for decades to spin finest yarn: planetary spinning pumps are the heart of every synthetic fibre spinning plant.

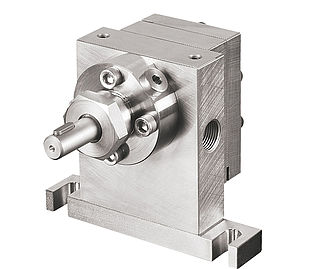

Spin finish dosing pumps do not only meter preparation fluids. They can also be used for the consistent dosing of water, perfume or even oils.

There are almost no limits to the use as a dosing pump in various industries. As a spinning pump it is only used for special applications.

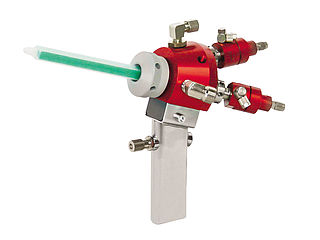

Predominantly used in spinning and adhesives technology, they offer the possibility of realizing two flow rates with minimal space and one motor drive only.

Product bores which are on both sides of the pump body allow the pump to be integrated directly into the production line.

They can be used for all applications. Direct installation in the product line does not require an additional clamping block.

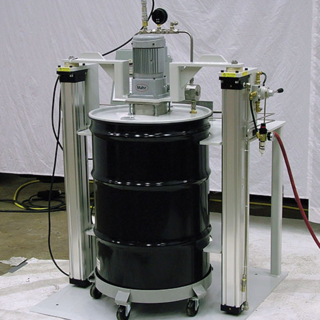

Discharge pumps ensure gentle discharge of polymer melts with low product shear. Booster pumps ensure a defined process pressure for downstream tools such as dies or extruders.

Gear pumps for the chemical industry, process pumps

Optimized metering pumps for chemical processes – low-pulsation gear pumps with high chemical resistance and precise metering

Paint metering pumps can also be used for robot applications. Even at short flushing cycles these pumps show excellent flushing results.

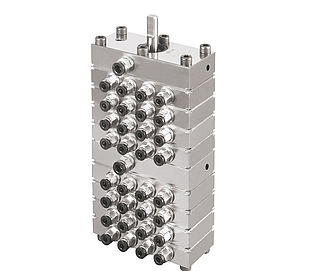

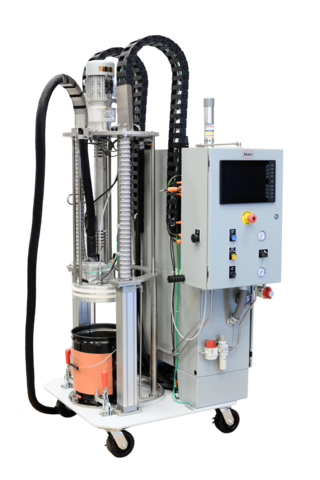

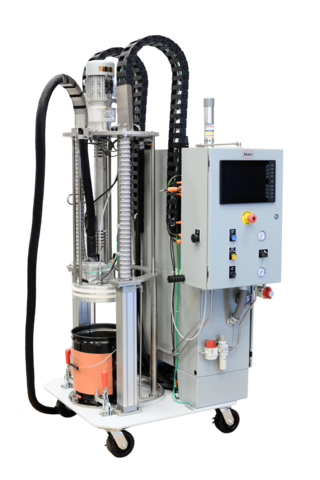

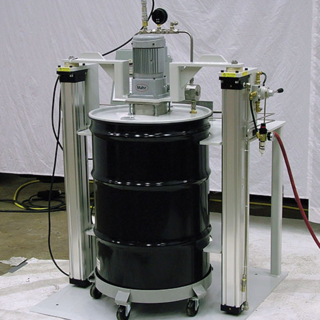

2part/3part mixing and dosing machine for small output quantities

Leistungsstark:

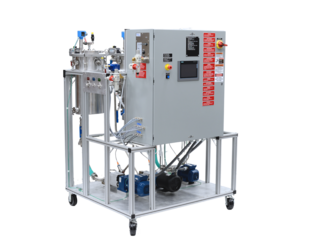

2K - nK Misch- und Dosiermaschine für hohe Ausstoßmengen.

2K - nK meter mix dispense machine for high material flow rates

2K - nK meter mix dispense machine for high material flow rates

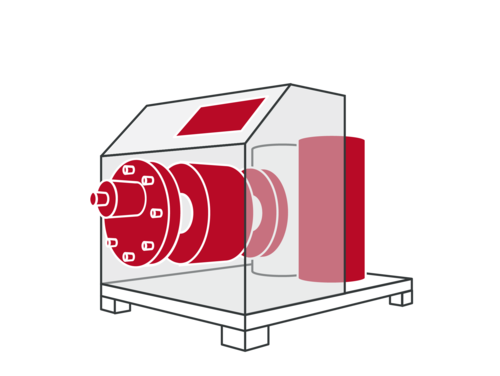

The mixing takes place exclusively through the flow movement of the components and the geometry of the mixing element.

The components are mixed by a rotating element in a mixing chamber.

The mixing takes place through the flow movement of the components in cooperation with the geometry and rotation of the mixing element.

Your Requirement – Our service

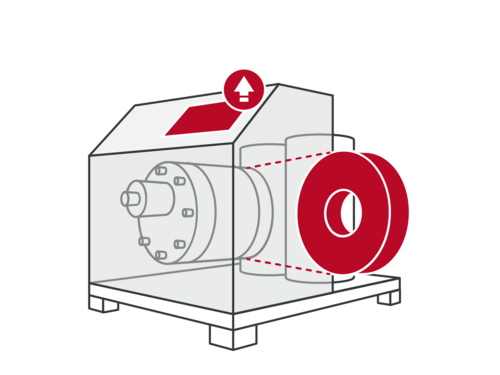

Exchange

From old to new – replacement of whole units for highest efficiency and profitability

Spare Parts Service

Replacement of defective single components and entire assemblies by the manufacturer

Commissioning

Smooth performance right from the start – supported by our experienced technicians

Repair

Visual and functional testing of all machine components

Machine Extension

Special requirements? We offer the right add-on

Material Tests

Examination of all requirements for technical feasibility

Conversion & Updates

We help to keep you up to date with the latest technology.

Maintenance

Smooth production processes thanks to regular maintenance of the machines

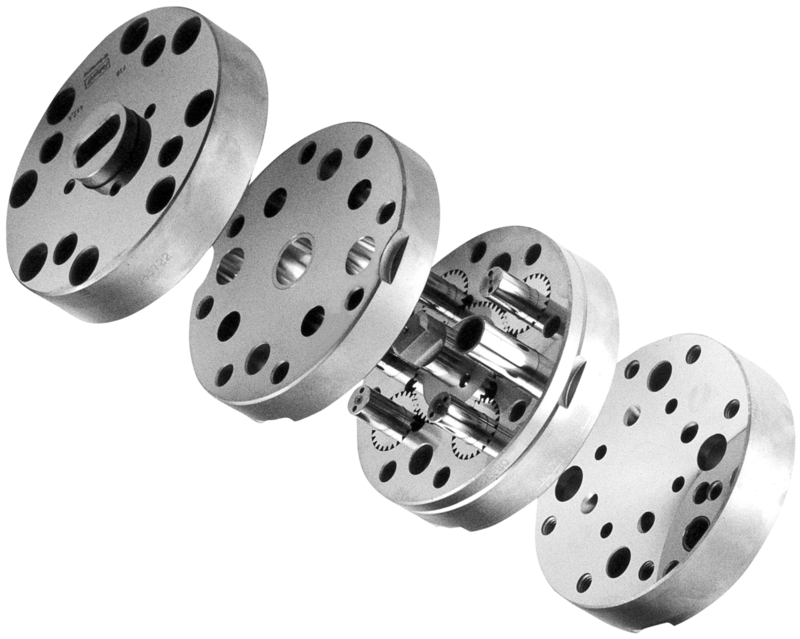

Mahr High-Precision Gear Metering Pumps

High-precision pumps are used for a variety of reasons: for example, because the application process cannot tolerate fluctuations in output or the end product must meet the highest demands. Gear pumps are naturally subject to wear - the decisive factors are the operating conditions. To ensure that pumps can maintain the required performance over many years, they should be checked.

We offer you a full range of services in our repair workshop from cleaning to repair. Our service technicians will also be pleased to repair the pumps in your factory.

+1 704 525 7128

Services in our Factory

Maintenance Contracts for your Mahr Product

Regular service intervals help to save costs and plan capacities reliably. With a service contract you can flexibly plan maintenance intervals and reduce or ideally avoid the number of unplanned production stops.

Contact us for more information!

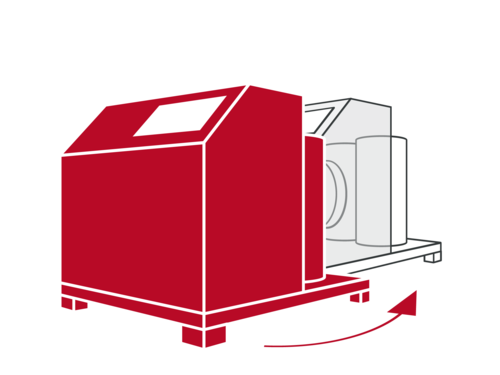

Meter Mix Dispense Machines for a Precise Mixing Ratio

By purchasing a Mahr machine you have decided on a high-quality product which supports your production process for the best production results. For preventive maintenance of your metering system we offer partial maintenance of single assemblies as well as complete maintenance and calibration of assemblies with the control system used. The aim is to ensure the best possible operational availability and to extend the service life of the machine by spare part supply, maintenance concepts and on-site service.

We offer you a full range of services from cleaning to repair in your factory or in our repair workshop.

+1 704 525 7128

Important Information for sending Products in

Please send in your products only with the completed declaration of decontamination and, if applicable, the safety data sheet. Please attach them visibly to the outside of the package or send these documents in advance. We may only accept and open your consignment on presentation of these documents. If these documents are missing, we are forced to return the shipment to you.

or use your own form.

Turn our knowledge into yours!

Our user training conveys not only necessary knowledge for optimum machine operation or pump maintenance but also improves your understanding of the entire system technology. Even the best machines cannot achieve much if they are not used perfectly. The knowledge we pass on to you enables you to optimize your products more efficiently.