Hochwertige Messtechnik für die Qualitätskontrolle in Messraum, Produktion, Wareneingang oder Entwicklung.

Zahnradpumpen & Misch- und Dosiermaschinen mit höchster Genauigkeit für die Verarbeitung von Flüssigkeiten und Pasten.

Hochgenaue Kugelführungen für spielfreie Hub- und Drehbewegungen beim Einsatz im Maschinen- und Vorrichtungsbau.

Einsatzbereiche von Mahr Maschinen

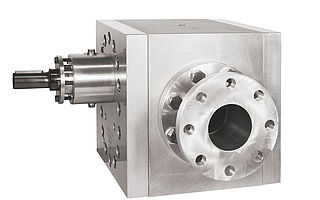

Proven use for decades to spin finest yarn: planetary spinning pumps are the heart of every synthetic fibre spinning plant.

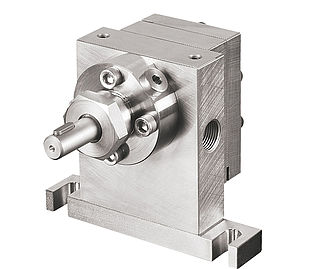

Spin finish dosing pumps do not only meter preparation fluids. They can also be used for the consistent dosing of water, perfume or even oils.

There are almost no limits to the use as a dosing pump in various industries. As a spinning pump it is only used for special applications.

Predominantly used in spinning and adhesives technology, they offer the possibility of realizing two flow rates with minimal space and one motor drive only.

Product bores which are on both sides of the pump body allow the pump to be integrated directly into the production line.

They can be used for all applications. Direct installation in the product line does not require an additional clamping block.

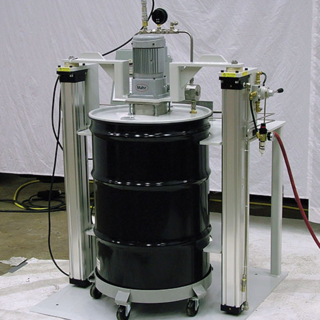

Discharge pumps ensure gentle discharge of polymer melts with low product shear. Booster pumps ensure a defined process pressure for downstream tools such as dies or extruders.

For highly accurate, low-pulsation dosing of liquids. The gear metering pumps achieve an efficient performance even at low viscosity and back pressure.

Paint metering pumps can also be used for robot applications. Even at short flushing cycles these pumps show excellent flushing results.

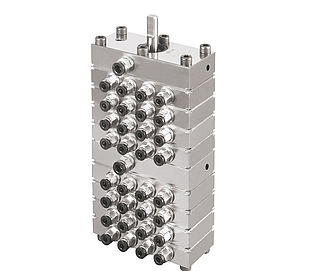

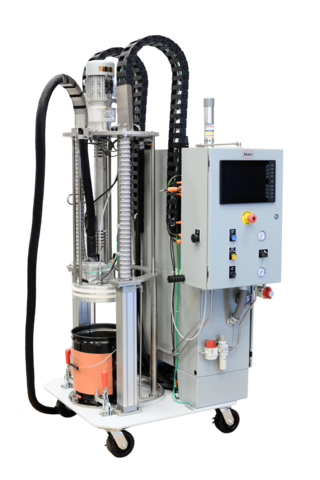

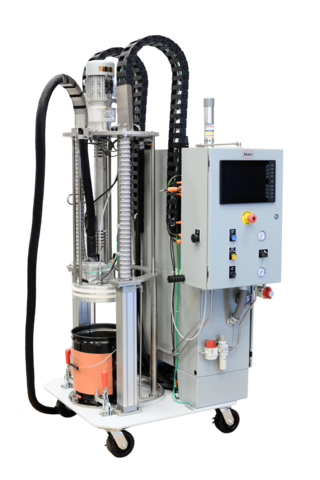

2part/3part mixing and dosing machine for small output quantities

Leistungsstark:

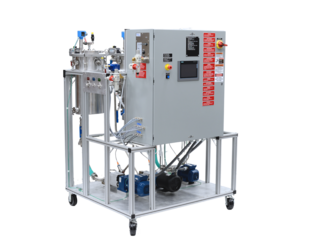

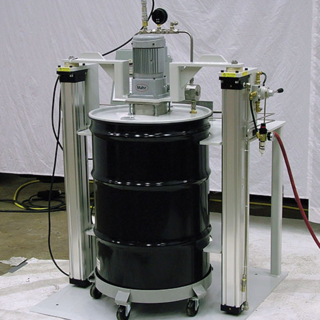

2K - nK Misch- und Dosiermaschine für hohe Ausstoßmengen.

2K - nK meter mix dispense machine for high material flow rates

2K - nK meter mix dispense machine for high material flow rates

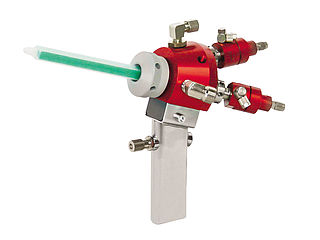

The mixing takes place exclusively through the flow movement of the components and the geometry of the mixing element.

The components are mixed by a rotating element in a mixing chamber.

The mixing takes place through the flow movement of the components in cooperation with the geometry and rotation of the mixing element.

What advantages offer Mahr gear metering pumps compared to other alternative pumps?

- low operating and maintenance costs

- low maintenance requirements

- each single part can be replaced separately

- long durability due to technically customized layout for user-specific operating data

| Flow cc/rev | 0.01 - 3,000 | ||

| Speed range U/min | 20 - 200 | ||

| Viscosity mPas | 0.5 - 100,000 | ||

| Operating temperature | room temperature up to 400 °C | ||

| Pump Material | in correlation to the metered liquids a variety of specialised steels and special materials are available | ||

| DLC coatings (others on request) | Diamond-Like Carbon (DLC) coating improves the wear resistancy | ||

| Medium to be pumped | all kind of liquids including corrosive and abrasive media | ||

The pump drive connection is available in following types:

- shaft type

- plug type

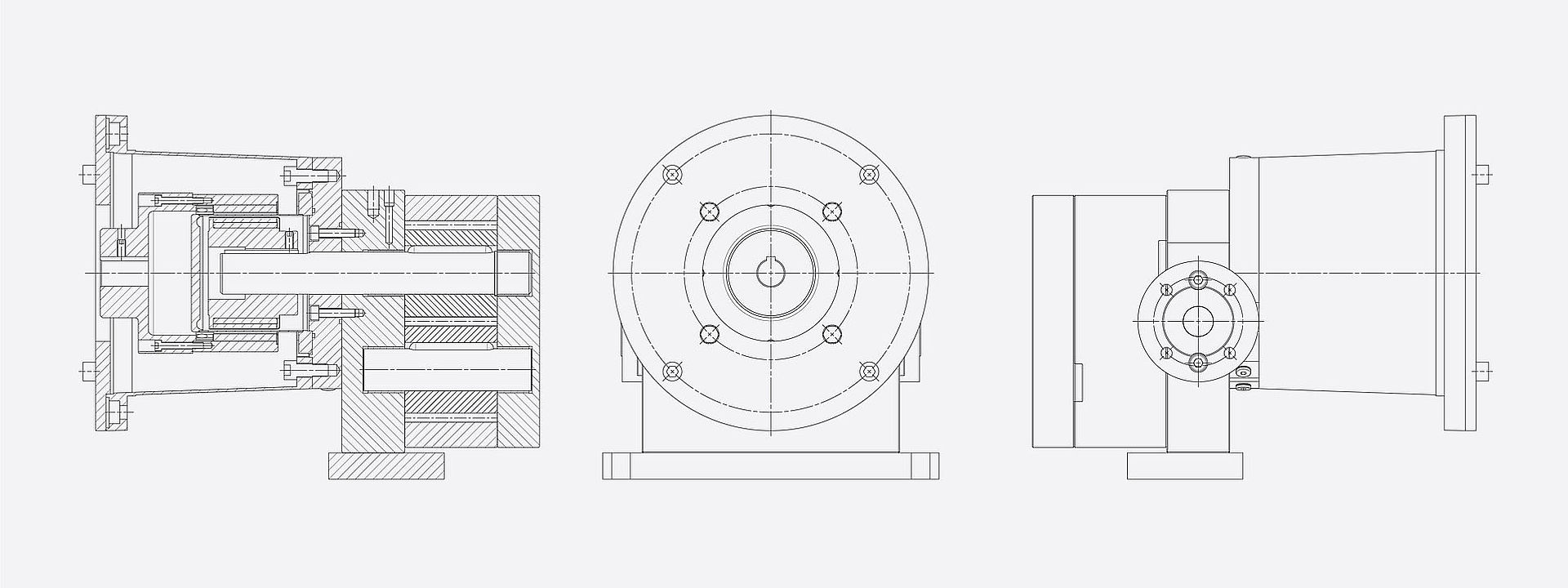

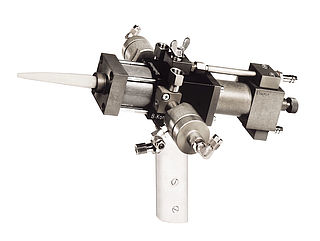

Gear metering pump with drive unit

- Base plate with mounting block

- Coupling

- curved tooth coupling

- cardan shaft

- all-steel coupling

- magnetic coupling

- Motor

- asynchronous gear motor

- servomotor / servo gear motor

- synchronous geared motor

The drive units are designed according to the operating conditions.

Sealing systems for the gear pumps

- stuffing box seal optionally with barrier liquid

- rotary shaft seal optionally with barrier liquid

- labyrinth seal

- mechanical seal, single, double and optionally with sealing liquid

- magnetic coupling

ATEX Directive 2014/34/EU

A version according to the Atex directive is available for the pump as well as for the drive.

Tempering of gear pump Electrical heating, liquid heating and cooling are available.

Further features The dosing pumps can be supplied with additional equipment according to requirements:

- speed control by inverter / servo controller

- pressure monitoring / control

- temperature monitoring / control

- flow monitoring / control

- evaluation options

- stand-alone dosing station or dosing module prepared for integration in machine environment

- communication to other machines or control systems

Do you have questions about our products?

Please contact us at +1 704 525 7128