Precise and Reliable

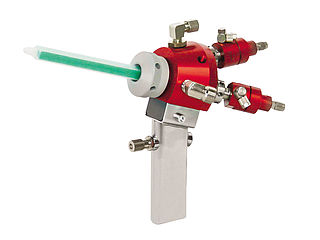

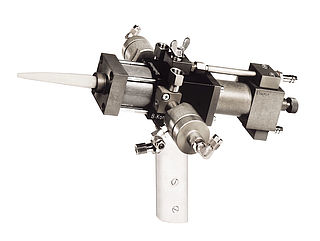

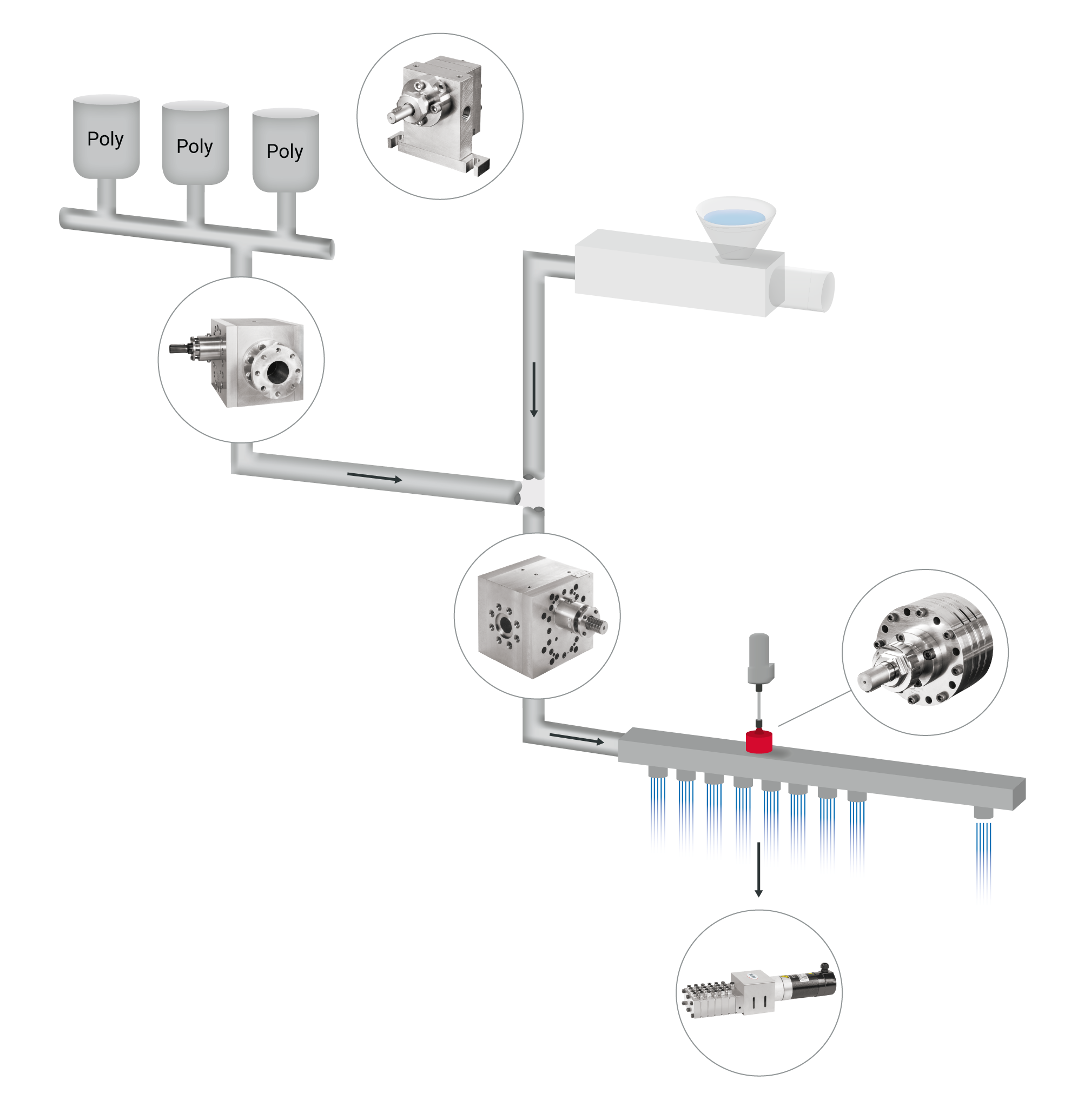

Hidden in the background and as precise as Swiss clockwork, Feinpruef gear pumps from Mahr deliver the substances from which the finest fibers are made. They deliver filaments of perfectly consistent thickness with precision down to the last thousandth of a millimeter over hundreds of kilometers of thread. Furthermore, they precisely and continuously meter the polymer melt and ensure that the best quality is delivered to the bobbin.

Industrial fiber production, an important wheel in our world today

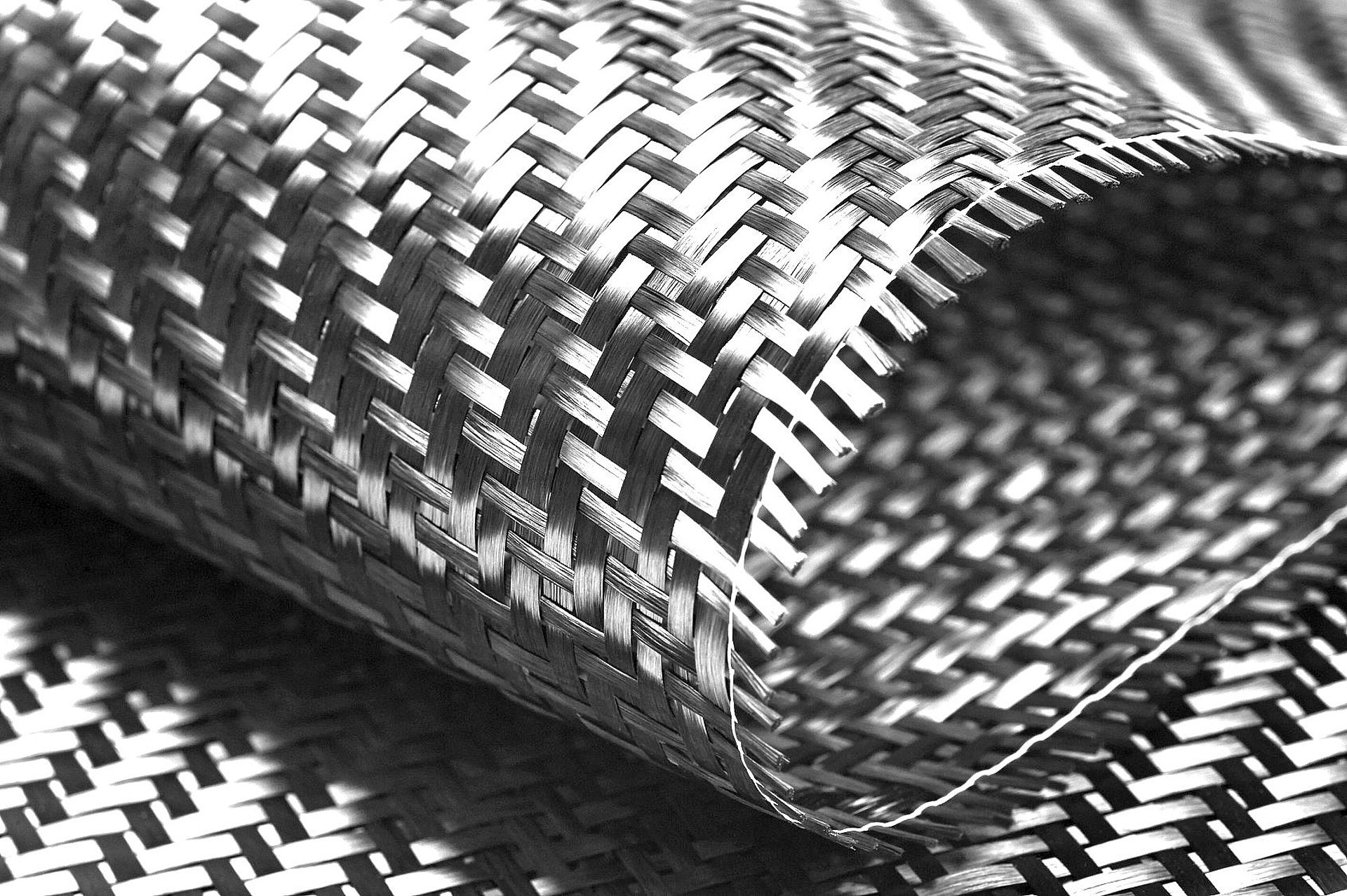

Fibers of natural origin are animal hair and plant fibers. These fibers are limited in length due to natural growth processes. There have been man-made fibers since the 1940s. They are made from natural (wood), synthetic polymers (e.g. polyester) or inorganic materials (e.g. glass fiber) and can be produced in endless lengths. Endless fibers are also called filaments. When talking about fiber, the layman inevitably thinks of a multifilament without knowing it, because a multifilament is what constantly accompanies us in our daily lives. A seemingly invisible bundle of fibers that have been brought together to form a thread. If you look at ladies' stockings with the designation 6 den, they are already quite transparent. On the other hand, at 80 den one speaks of opaque stockings. 1 Denier, that is the measure for the thread. 1 Denier corresponds to 1 gram per 9,000 meters of yarn. The modern term is dtex. That is 10,000 meters for 1 gram. Besides multifilaments there are also monofilaments – they consist of only one fiber. Monofilaments are known from fishing lines and fishing nets.

fiber types

Aramides, also referred as polyaramides or aromatic polyamides, are polyamides whose amide groups are bonded to aromatic groups. Aramides are rated among liquid crystal polymers (LCP). The most important types are poly(p-phenylene terephthalamide) (PPTA, trade names: Kevlar, Twaron) and poly(m-phenylene isophthalamide) (PMPI, trade names: Nomex, Teijinconex).

Cellulose is the main component of plant cell walls (about 50% by mass) and thus the most common organic compound and also the most common polysaccharide. Cellulose is also the most common biomolecule. It is unbranched and consists of several hundreds to tens of thousands of (β-1,4-glycosidically linked) β-D-glucose or cellobiose units. These high-molecular cellulose chains combine to form higher structures. As tear-resistant fibers they often fulfil static functions in plants. Cellulose differs from the polysaccharide chitin, which is also common in nature, by the absence of acetamide groups. Cellulose is important as a raw material for paper production, but also in the chemical industry and other areas.

Polyacrylonitrile (abbreviation PAN) is the polymer of acrylonitrile.

Polyamides (abbreviation PA) are linear polymers with regularly repeating amide bonds along the main chain. The amide group can be regarded as a condensation product of a carboxylic acid and an amine. The resulting bond is an amide bond which is hydrolytically seperable again. Polyamides are often used as construction materials due to their excellent strength and durability. They provide good chemical resistance to organic solvents but can easily be attacked by acids and oxidising chemicals.

Polyesters are polymers with ester functions -[-CO-O-]- in their main chain. Although polyesters also occur in nature, today they are more commonly understood to be a large family of synthetic polymers (plastics). This includes the frequently used polycarbonates (PC) and, above all, the technically important thermoplastic polyethylene terephthalate (PET). Another type are unsaturated polyester resins (UP resins), which turn into thermosets by curing and are used as a low-cost matrix resin in the field of fiber composites. In addition to this, aromatic polyesters can be arranged to form liquid-crystalline polymer chains, resulting in the characteristics profile of a high-performance plastic.

Polyethylene (abbreviation PE) is a thermoplastic material with a simplified structural formula produced by chain polymerisation of petrochemically produced ethene (CH2=CH2). Polyethylene is rated among polyolefins and is partially crystalline and non-polar. It is by far the most frequently used (standard) plastic worldwide and is primarily used for packaging. All types of polyethylene are characterised by high chemical resistance, good electrical insulation and good sliding performance. However, the mechanical properties are minor compared to other plastics.

Polyimides (abbreviation PI) are plastics whose most important structural attribute is the imide group. These include polysuccinimide (PSI), polybismaleimide (PBMI), polyimide sulfone (PISO) and polymethacrylimide (PMI). Polyimides, which contain further structural elements such as ester groups, amide groups etc., form their own substance groups such as polyetherimides (PEI), polyamideimides (PAI).

Polyolefins are polymers that are made from alkenes such as ethylene, propylene, 1-butene or isobutene by chain polymerization. Polyolefins are saturated hydrocarbons, which represent the largest group of plastics in terms of volume. They are semi-crystalline thermoplastics which are easy to process. They are characterised by good chemical resistance and electrical insulation properties. Polyolefins, with 11.2 million tons, represent about 47% of the total annual European consumption of plastics of 24.1 million tons.

Polypropylene (abbreviation PP) is a thermoplastic material produced by chain polymerisation of propene. It is rated among polyolefins and is partially crystalline and non-polar. Its characteristics are similar to those of polyethylene, but Polypropylene is slightly harder and more heat-resistant. Polypropylene is the second most frequently used standard plastic and is often used in packaging. In 2016, 17.66 million tons were used for flexible packaging material worldwide and 23 million tons of moulded plastic parts were produced.

Polystyrene (abbreviation PS) is a transparent, foamed white, amorphous or partially crystalline thermoplastic. Amorphous polystyrene is a widely used (standard) plastic that is applied in many areas of daily life. Expanded polystyrene (EPS, mainly known under the trade name Styropor) and extruded polystyrene (XPS) are used as foams.

Fluoropolymers or also fluoroplastics are polymers based on fluorocarbons with multiple carbon-fluorine bonds, in which a large part or even all of the hydrogens otherwise contained are usually replaced by fluorine. Fluoropolymers are among others characterised by their high resistance to chemicals and temperature. They are elastic to viscous, but usually not very solid. Just like fluorocarbons, they are not affected by the Van der Waals force, like hydrocarbons, and therefore they behave anti-adhesive and friction-reducing. The multiple carbon-fluorine bonds provide them with high chemical resistance.

Polyurethanes (abbreviation PUR; in linguistic usage also PU) are plastics or synthetic resins that are produced from the polyaddition reaction of dialcohols (diols) or polyols with polyisocyanates. A characteristic feature of polyurethanes is the urethane group. Diols and diisocyanates generate linear polyurethanes, crosslinked polyurethanes can be produced by reacting triisocyanate-diisocyanate mixtures with triol-diol mixtures. The characteristics of PU can be varied within a wide range. Depending on the degree of crosslinking and/or the isocyanate or OH component used it is possible to create thermosets, thermoplastics or elastomers. In terms of quantity, polyurethane foams are most important as flexible or rigid foam. Polyurethanes are also used as moulding compounds for compression moulding, as casting resins (isocyanate resins), as (textile) elastic fibers, polyurethane coatings and as polyurethane adhesives.

Polyvinyl alcohol (abbreviation PVAL or PVOH) is a thermoplastic synthetic material, which is produced as a white to yellowish powder usually by saponification (hydrolysis) of polyvinyl acetate (PVAC). The direct synthesis process is not possible. PVAL is resistant to almost all water-free organic solvents. Partially saponified varieties of PVAL with approx. 13% PVAC are easily soluble in water. With increasing degree of saponification the water solubility decreases.

Polyvinyl chloride (abbreviation PVC) is a thermoplastic polymer produced by chain polymerisation from the monomer vinyl chloride. PVC is the third most important polymer for plastics behind polyethylene and polypropylene. PVC plastics are categorised ad rigid and soft PVC. Rigid PVC is used, for example, to manufacture window profiles, pipes and records. Soft PVC contains plasticizers that make the material elastic. It is used for example for cable sheathing and floor coverings.

Viscose fibers are chemical fibers (regenerated fibers) made from regenerated cellulose, which can be produced both as filament yarn and as spun fiber. They are industrially spun using the viscose process, the most common wet spinning process. Regenerated cellulose is chemically identical to native fiber cellulose, such as cotton, but has a different elementary lattice in the ordered ranges, namely that of cellulose II or hydrate cellulose. The state of order is about half as large as in native cellulose.

The production process takes place in three main stages:

- Production of the spinning solution (viscose)

- Spinning of the filaments

- Subsequent treatment of the spun threads

Source: Wikipedia (language: german), accessed on 05.05.2020

What is Mahr doing in the synthetic fiber sector?

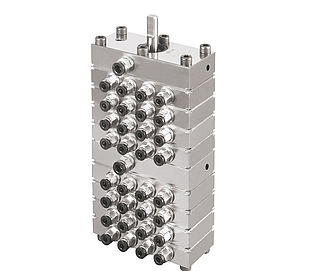

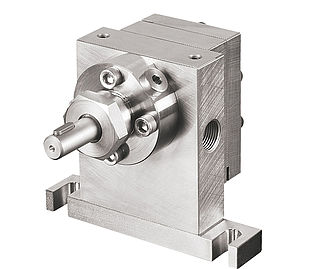

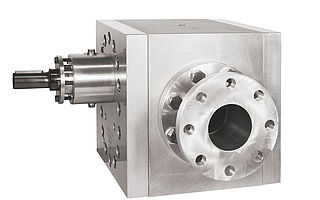

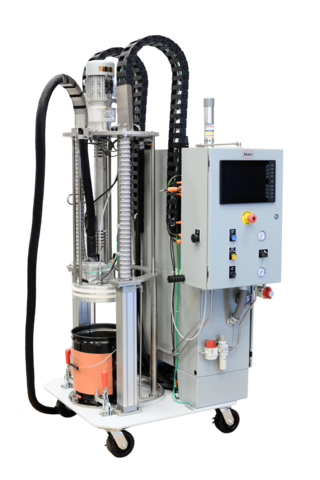

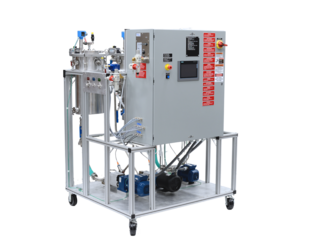

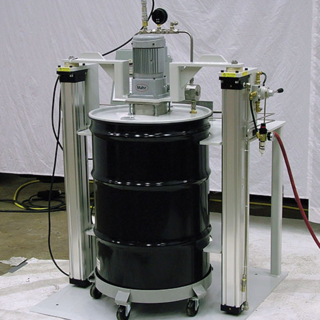

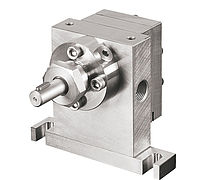

The gear metering pump is an elementary component of the synthetic fiber plant for the production of high-quality fibers. Therefore, we advise our customers individually and in detail to find the right solution for every task and application. Due to our long experience, we can look back on a comprehensive and proven product portfolio of high-precision gear metering pumps. Design modifications are implemented by our engineering department to ensure a perfect design for the fiber production process.

Our pumps convince with highest precision, wear, corrosion and temperature resistance. They meet all requirements of polymer melt, as well as wet and dry spinning technology.

They are used among other things for the production of home textiles such as functional clothing, microfiber textiles and swimwear. In the field of technical yarns, they are used for car tires, safety belts, V-belts, airbag fabrics or protective and space suits.

Mahr Gear Metering Pumps for the Synthetic Fiber Production Process

Do you have questions about our products?

Please contact us at +1 704 525 7128