High-quality metrology for quality control in the measuring room, production, incoming goods and development.

Zahnradpumpen & Misch- und Dosiermaschinen mit höchster Genauigkeit für die Verarbeitung von Flüssigkeiten und Pasten.

Hochgenaue Kugelführungen für spielfreie Hub- und Drehbewegungen beim Einsatz im Maschinen- und Vorrichtungsbau.

Einsatzbereiche von Mahr Maschinen

Proven use for decades to spin finest yarn: planetary spinning pumps are the heart of every synthetic fibre spinning plant.

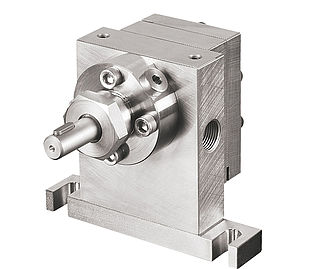

Spin finish dosing pumps do not only meter preparation fluids. They can also be used for the consistent dosing of water, perfume or even oils.

There are almost no limits to the use as a dosing pump in various industries. As a spinning pump it is only used for special applications.

Predominantly used in spinning and adhesives technology, they offer the possibility of realizing two flow rates with minimal space and one motor drive only.

Product bores which are on both sides of the pump body allow the pump to be integrated directly into the production line.

They can be used for all applications. Direct installation in the product line does not require an additional clamping block.

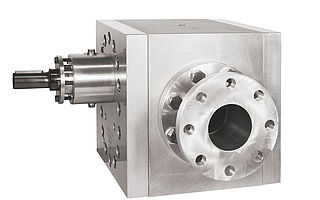

Discharge pumps ensure gentle discharge of polymer melts with low product shear. Booster pumps ensure a defined process pressure for downstream tools such as dies or extruders.

For highly accurate, low-pulsation dosing of liquids. The gear metering pumps achieve an efficient performance even at low viscosity and back pressure.

Paint metering pumps can also be used for robot applications. Even at short flushing cycles these pumps show excellent flushing results.

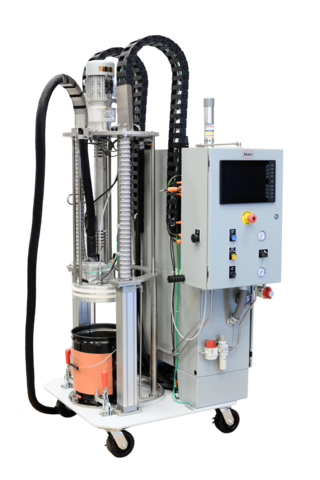

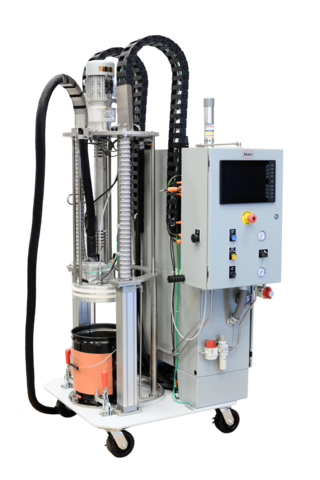

The lightweight:

2K - 3K mixing and dosing machine for small output quantities.

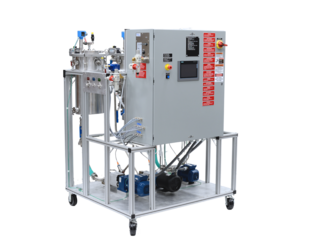

Leistungsstark:

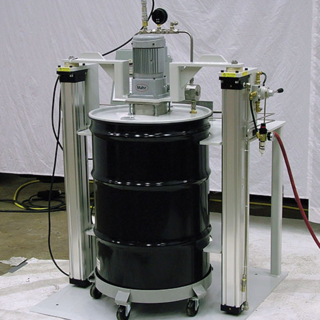

2K - nK Misch- und Dosiermaschine für hohe Ausstoßmengen.

2K - nK meter mix dispense machine for high material flow rates

2K - nK meter mix dispense machine for high material flow rates

The mixing takes place exclusively through the flow movement of the components and the geometry of the mixing element.

The components are mixed by a rotating element in a mixing chamber.

The mixing takes place through the flow movement of the components in cooperation with the geometry and rotation of the mixing element.

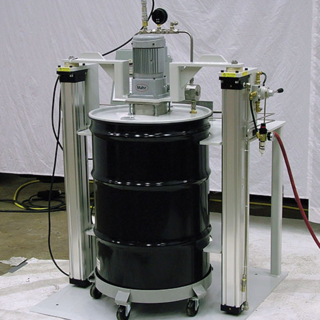

MarMax PS for production output rates

2part/multi part meter mix dispense machines which are designed for high material flow rates and a max. material output of up to 10 gal/min.

Different tank sizes are available to suit.

High-capacity production

- Flexible application

- Suitable for a wide range of applications

- Individually configurable

- Automatic refill control and refill device

The MarMax PS is a production machine customized to meet your specific needs and application requirements. Designed, built and programed in the USA by a team that is available to give you the support you need. UL and CSA certified designs available. Customizable HMI interface to optimize operation for your individual task and ensure your success.

| Flow rate | Up to 10 gal/min |

|---|---|

| Mixing ratio | Infinitely variable |

| Material tank sizes | 5, 10, 20, 30, 40, 60 and 80 gal (larger sizes to suit) |

| Conveying element | Gear metering pump |

| Remote servicing | Remote service capability integrated |

| Tank filling | Manual |

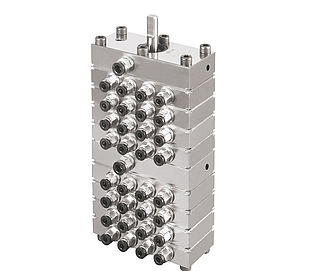

| Control system | IFM with IO-Link, SIemens or Allen-Bradley |

| Operation via colour touch screen panel | 7, 10, 12 or 15" depending on system complexity |

| Heating | Unheated (optionally heating) |

| Mixing Head | Suited to product and process |

- Gear flow meter / screw flow meter / coriolis flow meter / flow meter virtual

- Gear metering pump with magnetic coupling

- Alternative pump designs to suit unique applications

- Pressure monitoring on suction side

- Flushing medium container (5 or 10 gal)

- Shot counter

- Vacuum system

- Automatic refill control and equipment

- Heating for metering pump

- Recirculation - short or long

Suitable for these applications:

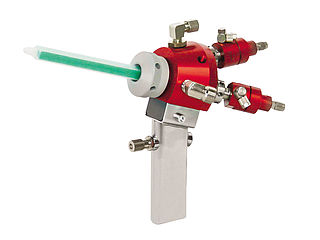

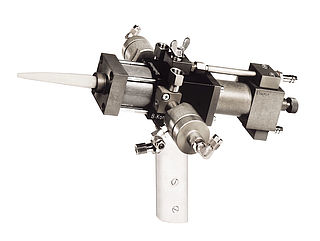

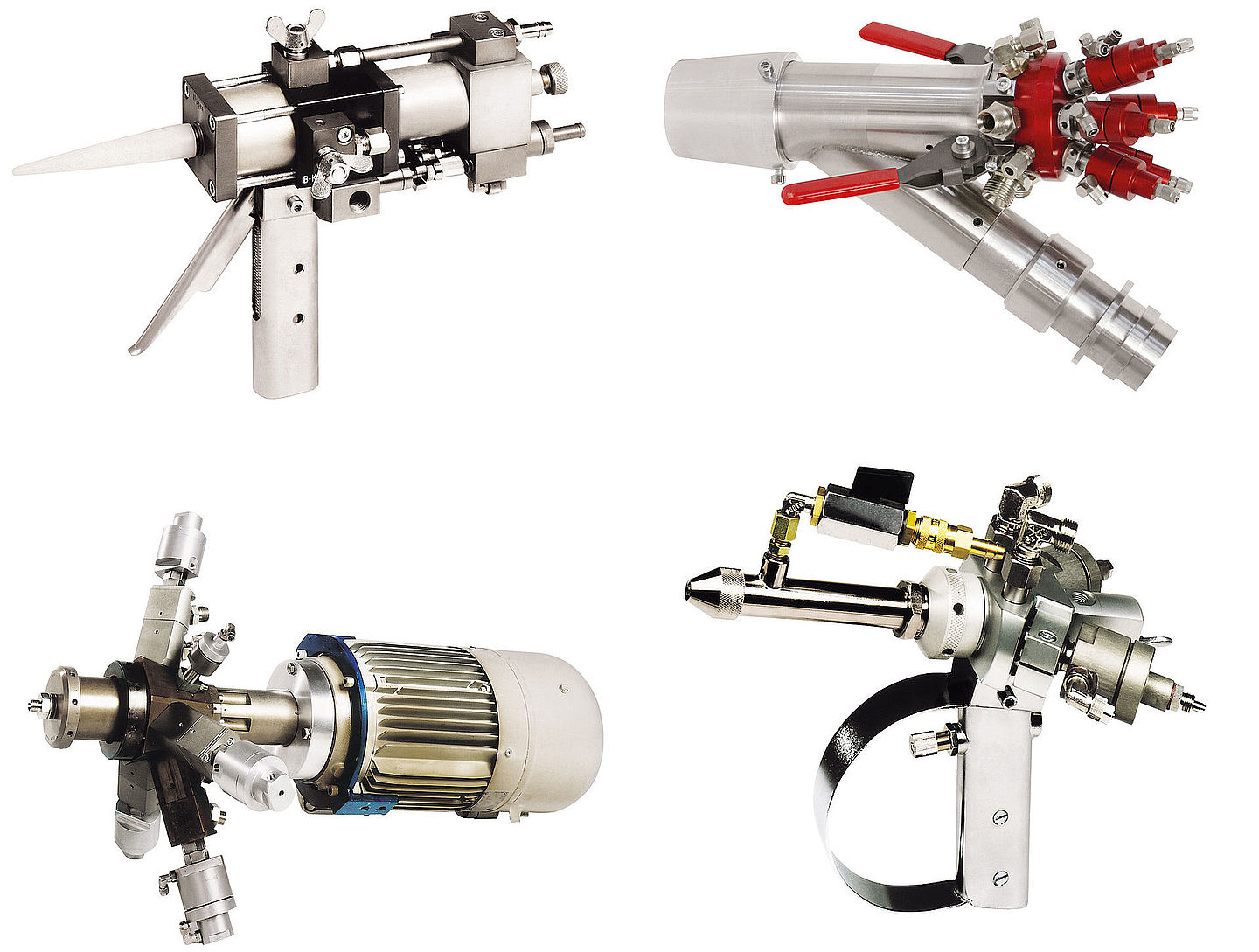

Mixing Heads – the mixture makes the difference

A perfectly customized mixing head guarantees the best mixing quality and exact discharge capacity. In order to select the suitable mixing head, we analyse the production process considering the operating parameters, such as material characteristics, the emission and the mixing ratio.

Do you have questions about our products?

Please contact us at +1 704 525 7128