Hochwertige Messtechnik für die Qualitätskontrolle in Messraum, Produktion, Wareneingang oder Entwicklung.

Zahnradpumpen & Misch- und Dosiermaschinen mit höchster Genauigkeit für die Verarbeitung von Flüssigkeiten und Pasten.

Hochgenaue Kugelführungen für spielfreie Hub- und Drehbewegungen beim Einsatz im Maschinen- und Vorrichtungsbau.

Einsatzbereiche von Mahr Maschinen

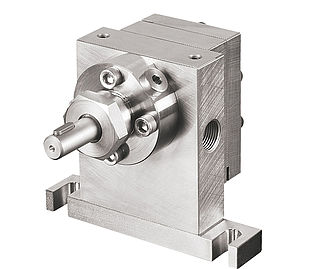

Proven use for decades to spin finest yarn: planetary spinning pumps are the heart of every synthetic fibre spinning plant.

Spin finish dosing pumps do not only meter preparation fluids. They can also be used for the consistent dosing of water, perfume or even oils.

There are almost no limits to the use as a dosing pump in various industries. As a spinning pump it is only used for special applications.

Predominantly used in spinning and adhesives technology, they offer the possibility of realizing two flow rates with minimal space and one motor drive only.

Product bores which are on both sides of the pump body allow the pump to be integrated directly into the production line.

They can be used for all applications. Direct installation in the product line does not require an additional clamping block.

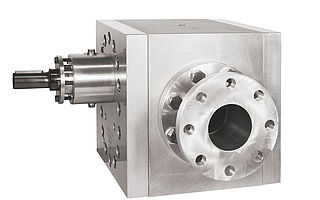

Discharge pumps ensure gentle discharge of polymer melts with low product shear. Booster pumps ensure a defined process pressure for downstream tools such as dies or extruders.

For highly accurate, low-pulsation dosing of liquids. The gear metering pumps achieve an efficient performance even at low viscosity and back pressure.

Paint metering pumps can also be used for robot applications. Even at short flushing cycles these pumps show excellent flushing results.

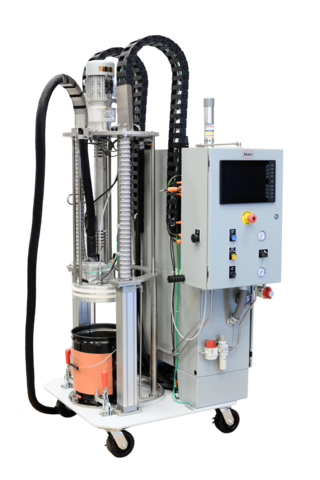

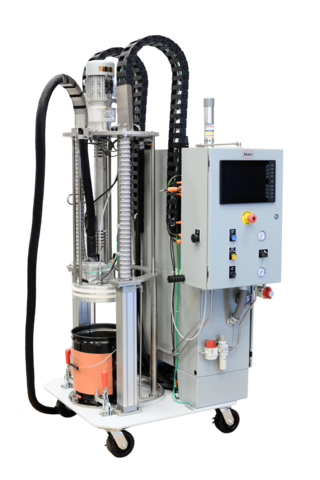

2part/3part mixing and dosing machine for small output quantities

Leistungsstark:

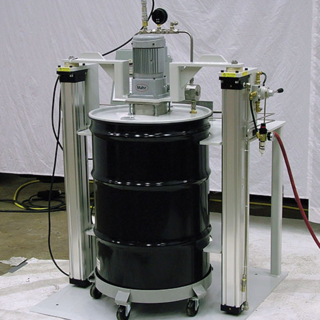

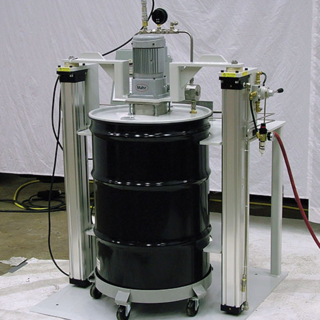

2K - nK Misch- und Dosiermaschine für hohe Ausstoßmengen.

2K - nK meter mix dispense machine for high material flow rates

2K - nK meter mix dispense machine for high material flow rates

The mixing takes place exclusively through the flow movement of the components and the geometry of the mixing element.

The components are mixed by a rotating element in a mixing chamber.

The mixing takes place through the flow movement of the components in cooperation with the geometry and rotation of the mixing element.

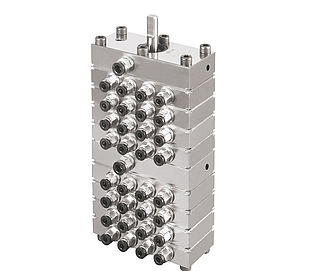

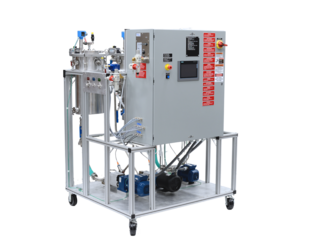

Tank Based Metering System

Metering system with day tank to provide a buffer during refilling and container changeover

Liquid Metering SystemTank design

Mahr Metering Systems’ liquid metering system with day tank is an open or closed loop single stream design. The unit is designed to continuously meter liquids of varying characteristics, viscosities and densities.

- open or closed loop

- flow rate accuracy better than +/- 0.5%

- continuous flow monitoring even during refill cycle

- recirculation mode optional

A flow meter based system allows continuous monitoring of flow even while refilling the day tank. This is not possible with loss-in-weight designs using scales. A recirculation option can be provided for applications requiring discontinuous dispensing and eliminate flow variation during system start/stop when a recirculation loop is not provided. Controls can be stand alone or integrated with existing systems. Mahr provides customized systems to maximize flexibility to meet customer needs.

Versatile, modular construction:

Mahr's liquid metering system can be sized for pilot plants or higher-volume full production facilities. Flow rate accuracy for each stream is better that +/- 0.5% of the setpoint. This machine can be used independently or coupled with any of Mahr’s other machine to create a fully custom system tailored for the process requirements.

| Flow rate | Up to 4 gal/min (higher flow rates possible) |

|---|---|

| Material tank sizes | 1.0, 1.5, 2.0, 2.5, 5, 10, 20, and 30 gal (larger sizes to suit) |

| Conveying element | Gear metering pump |

| Remote servicing | Capability optional |

| Operation via colour touch screen panel | Option |

| Pump range | 0.2 to 200 cc/rev |

| Max Viscosity | 50000cP |

| Gearmotor | 0.25 to 30hp, 1800rpm, 20:1 |

| Operating voltage | 230/460 VAC, 60Hz, 3 phase |

| Air Pressure | 6 bar (87 psi) |

| Weight | varies |

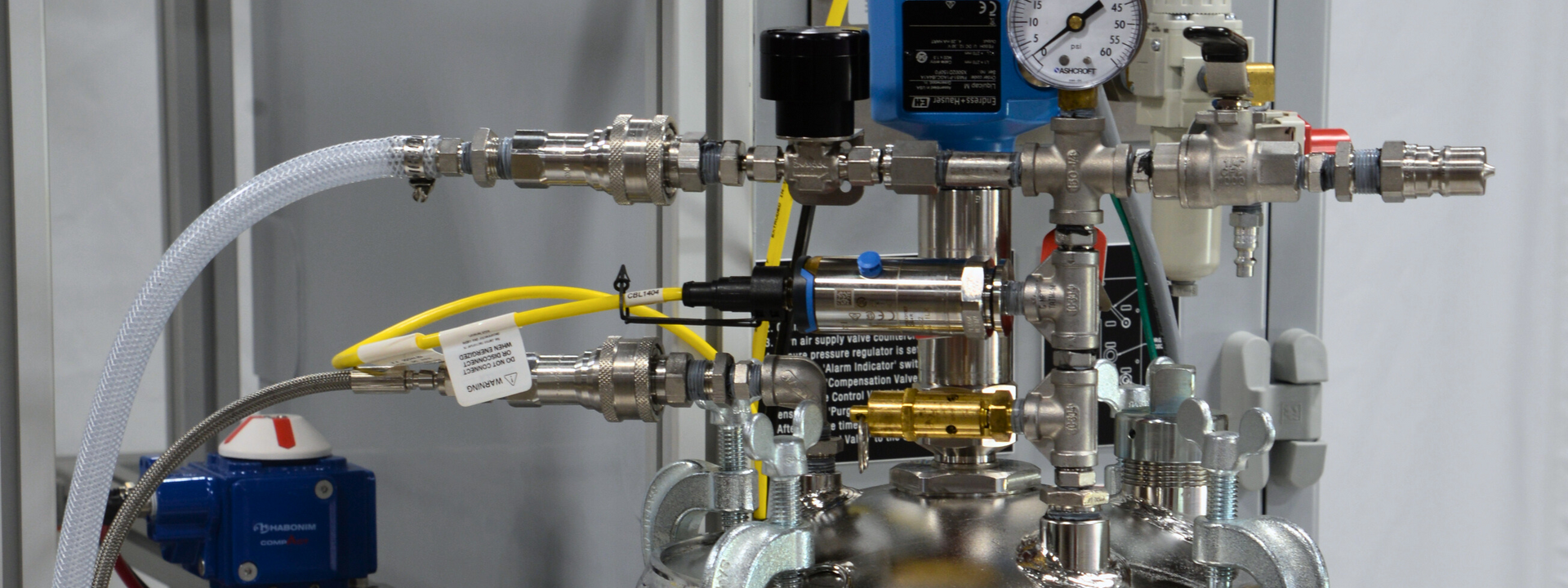

Mass flow meters (Gear)

Pressure Transducer

System heating options

Nitrogen blanket on tank

Automatic tank refill

Degassing cycle for viscous material

Suitable for these applications:

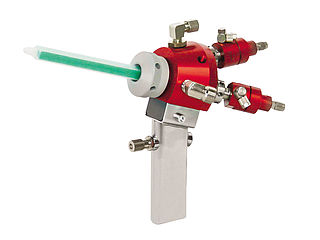

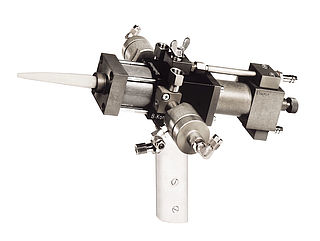

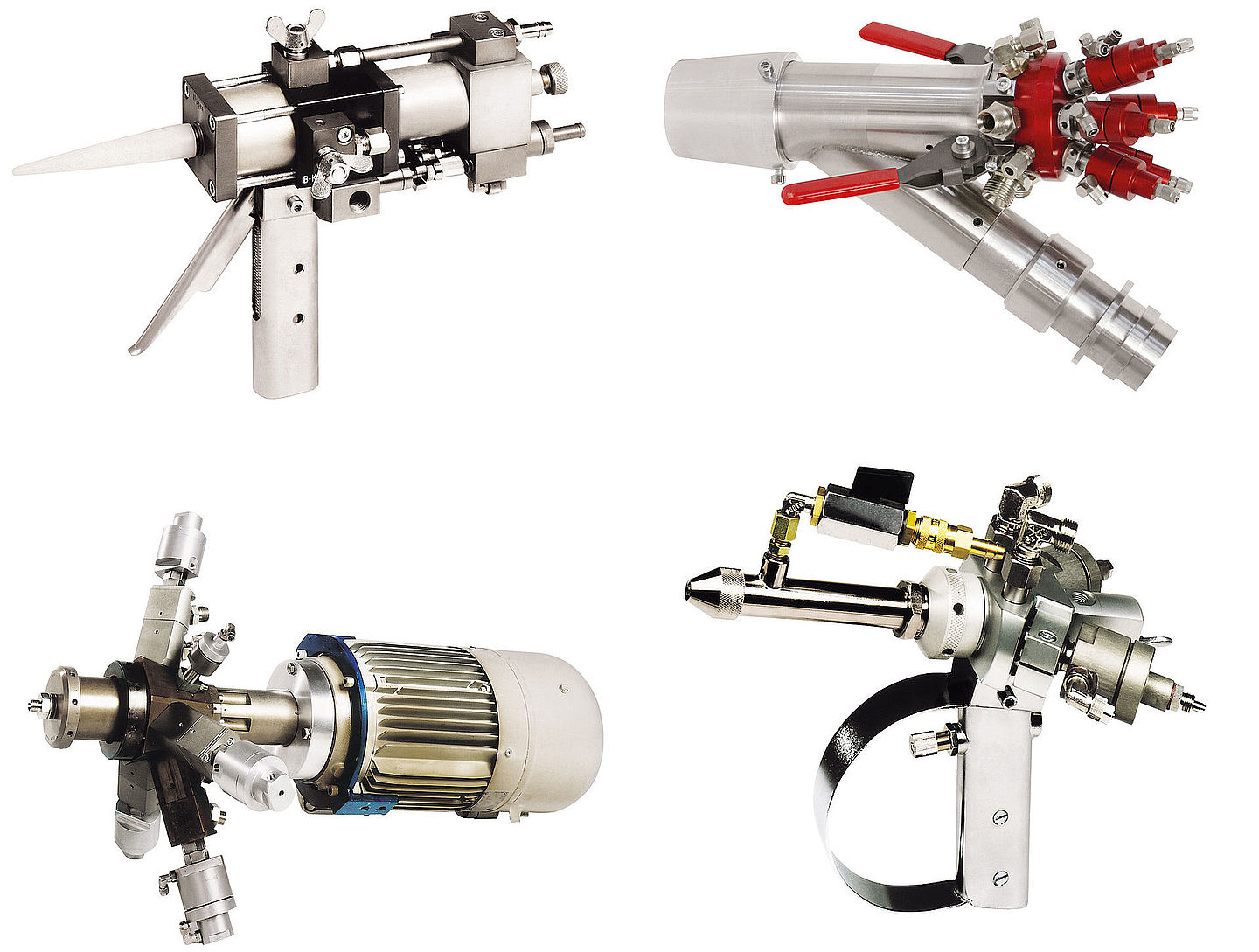

Mixing Heads – the mixture makes the difference

A perfectly customized mixing head guarantees the best mixing quality and exact discharge capacity. In order to select the suitable mixing head, we analyze the production process considering the operating parameters, such as material characteristics, the emission and the mixing ratio.

Do you have questions about our products?

Please contact us at +1 704 525 7128