High-quality metrology for quality control in the measuring room, production, incoming goods and development.

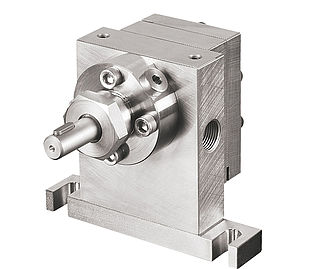

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

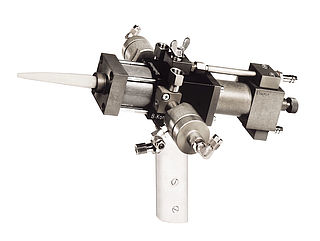

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

Pioneering machine solutions for the construction industry with high efficiency and advanced technology

Proven use for decades to spin finest yarn: planetary spinning pumps are the heart of every synthetic fibre spinning plant.

Spin finish dosing pumps do not only meter preparation fluids. They can also be used for the consistent dosing of water, perfume or even oils.

There are almost no limits to the use as a dosing pump in various industries. As a spinning pump it is only used for special applications.

Predominantly used in spinning and adhesives technology, they offer the possibility of realizing two flow rates with minimal space and one motor drive only.

Product bores which are on both sides of the pump body allow the pump to be integrated directly into the production line.

They can be used for all applications. Direct installation in the product line does not require an additional clamping block.

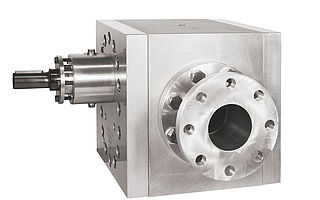

Discharge pumps ensure gentle discharge of polymer melts with low product shear. Booster pumps ensure a defined process pressure for downstream tools such as dies or extruders.

Gear pumps for the chemical industry, process pumps

Optimized metering pumps for chemical processes – low-pulsation gear pumps with high chemical resistance and precise metering

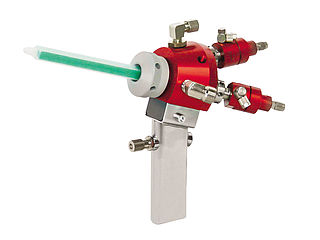

Paint metering pumps can also be used for robot applications. Even at short flushing cycles these pumps show excellent flushing results.

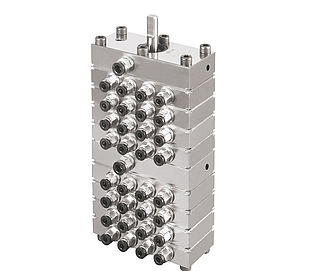

Solutions for material preparation, conditioning and supply to the meter mix dispense machine.

Lightweight design:

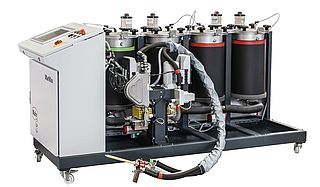

2C - 3C Meter Mix Dispense Machine for low flow rates

Our allrounder:

1C - 4C Meter Mix Dispense Machine for low to medium flow rates

Compact and efficient:

2C - 4C Meter Mix Dispense Machine with an output of up to 10 l/min

High-capacity:

2C - nC Meter Mix Dispense Machine for high material flow rates

Customised solutions:

perfectly tailored to suit your application

The mixing takes place exclusively through the flow movement of the components and the geometry of the mixing element.

The components are mixed by a rotating element in a mixing chamber.

The mixing takes place through the flow movement of the components in cooperation with the geometry and rotation of the mixing element.

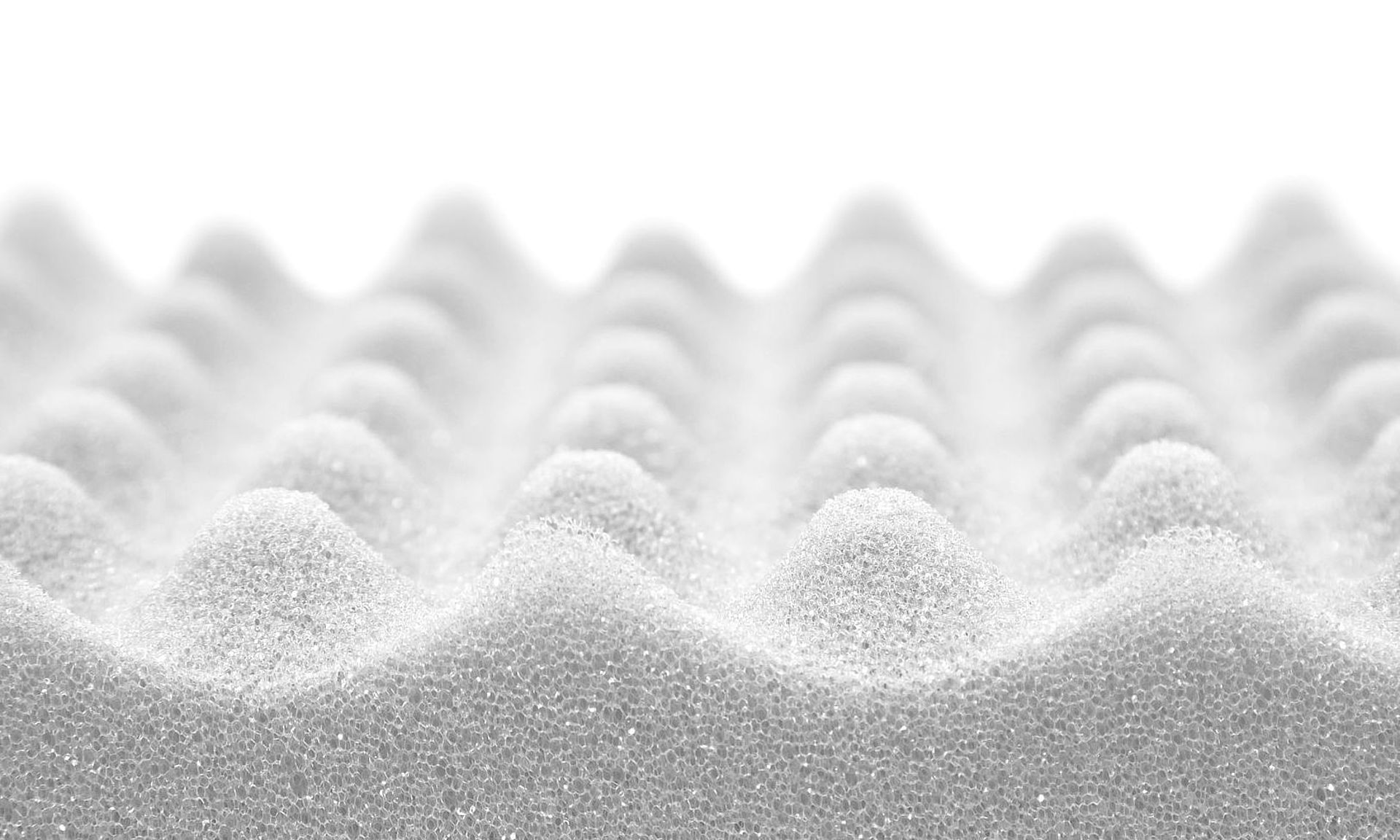

Polyurethanes have been around since the 1940s

Nowadays people hear and read a lot about the materials, often in their common abbreviations PU or PUR. But what exactly are polyurethanes?In simple words: Plastics, whose applications are extremely versatile. They can be encountered almost everywhere in our everyday life, in the living room as armchair cushion, on the way to work in the car or public transports, as well as in many technical applications. And how are polyurethanes made? As general initial substances are polyols, isocyanates and catalysts. The polyaddition reaction of these substances produces polyurethane, which gains its specific properties through different crosslinking and different initial substances respectively to its application. In general, polyurethanes can be classified as foams and cell-free PUR elastomers.

Polyurethanes are adjustable and therefore they can be assigned to fulfil specific properties

Processing of Polyurethanes

Our experience of more than 4 decades in polyurethane processing is reflected today in the variety of our machine technology and our expertise in various processes. Our meter mix dispense technology is specialized for the low pressure range application.

Where can Polyurethane be found?

- Furniture cushion

- Insulation

- Bumpers

- Shock absorber

- Flooring

- Assembly foam

- Armrests

- Sealing

- Shoe soles

- Airbag covers

- Ground sealing

- Cable sheathing

- Outdoor clothing

- Panel coating

- Windscreen bonding

- Mattresses

- Adhesive bonding applications

- Vacuum cleaner housing

- Refrigerators

- Electronic element encapsulation

- Buffer damper

- Pipe coating