High-quality metrology for quality control in the measuring room, production, incoming goods and development.

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

Pioneering machine solutions for the construction industry with high efficiency and advanced technology

Proven use for decades to spin finest yarn: planetary spinning pumps are the heart of every synthetic fibre spinning plant.

Spin finish dosing pumps do not only meter preparation fluids. They can also be used for the consistent dosing of water, perfume or even oils.

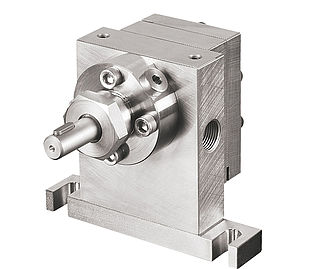

There are almost no limits to the use as a dosing pump in various industries. As a spinning pump it is only used for special applications.

Predominantly used in spinning and adhesives technology, they offer the possibility of realizing two flow rates with minimal space and one motor drive only.

Product bores which are on both sides of the pump body allow the pump to be integrated directly into the production line.

They can be used for all applications. Direct installation in the product line does not require an additional clamping block.

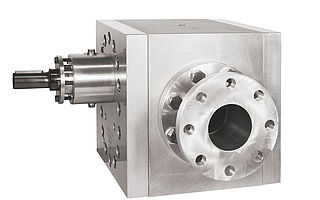

Discharge pumps ensure gentle discharge of polymer melts with low product shear. Booster pumps ensure a defined process pressure for downstream tools such as dies or extruders.

Gear pumps for the chemical industry, process pumps

Optimized metering pumps for chemical processes – low-pulsation gear pumps with high chemical resistance and precise metering

Paint metering pumps can also be used for robot applications. Even at short flushing cycles these pumps show excellent flushing results.

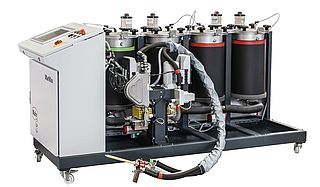

Solutions for material preparation, conditioning and supply to the meter mix dispense machine.

Lightweight design:

2C - 3C Meter Mix Dispense Machine for low flow rates

Our allrounder:

1C - 4C Meter Mix Dispense Machine for low to medium flow rates

Compact and efficient:

2C - 4C Meter Mix Dispense Machine with an output of up to 10 l/min

High-capacity:

2C - nC Meter Mix Dispense Machine for high material flow rates

Customised solutions:

perfectly tailored to suit your application

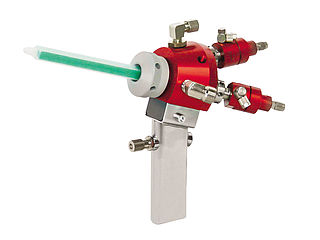

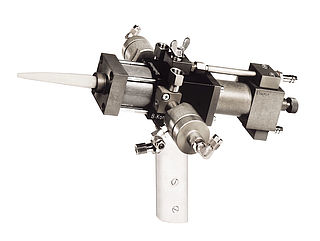

The mixing takes place exclusively through the flow movement of the components and the geometry of the mixing element.

The components are mixed by a rotating element in a mixing chamber.

The mixing takes place through the flow movement of the components in cooperation with the geometry and rotation of the mixing element.

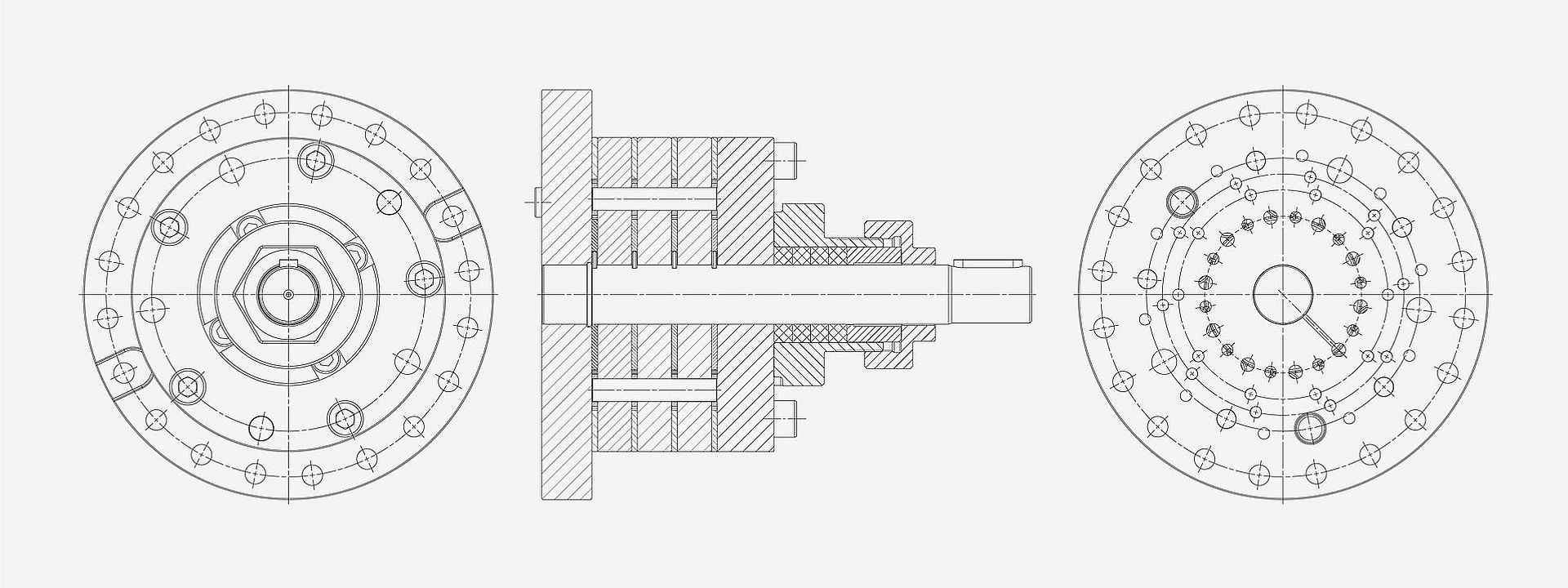

MarSpin – Planetary Spinning Pumps

Planetary spinning pumps – representing the heart of a spinning plant. They are used in large quantities. Tight production tolerances of the pumps, reliability and long lifetime are the key words for a high-quality yarn and customer satisfaction. Feinpruef spinning pumps of Mahr Metering Systems do guarantee to withstand toughest process conditions to finally spin and deliver a first-class quality yarn to the winder.

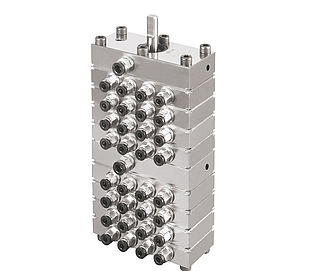

The special feature of planetary spinning pumps is the dosing of a material flow into up to 64 equal individual streams. These pumps are not only used for production of many different synthetic fibre and yarn, of that, for example, micro fibre textiles, tights, spandex, protective clothing and even astronautic overalls will be made. Planetary spinning pumps are also used for applications of dosing glue & adhesives and almost all kinds of fluids.

| Dimensions ø mm | 90 | 100 | 120 | 130 | 138 | 146 | 160 | 180 |

|---|---|---|---|---|---|---|---|---|

| Flow cc/rev | 0.3 - 4.8 | 0.1 - 4.8 | 0.2 - 6 | 6 - 12 | 0.3 - 4.8 | 0.3 - 6 | 10 - 30 | 0.3 - 2.4 |

| Number of outlets | 3 - 8 | 2 - 8 | 2 - 12 | 2 - 16 | 8 - 16 | 8 - 32 | 2 - 4 | 24 - 64 |

| Counter pressure bar (max) | 400 | 400 | 400 | 400 | 400 | 400 | 500 | 300 |

| Material | Material properties | Field of application | Permissible operating temperature max. | Permissible cleaning temperature max. |

|---|---|---|---|---|

| F16 | high tungsten, vanadium and chromium alloyed high speed steel |

| 450°C 840°F | 550°C 1020°C |

| F24 | molybdenum, tungsten, vanadium and chromium alloyed high speed steel |

| 450°C 840°F | 550°C 1020°F |

| Hastelloy | acid-resistant nickel alloy, additions of molybdenum and chromium |

| 250°C 480°F | 300°C 570°F |

| N19 | high chromium alloyed stainless steel, additions of molybdenum and vanadium |

| 180°C 356°F | 200°C 392°F |

| N31 | high chromium alloyed stainless steel, additions of molybdenum and vanadium Can be used in combination with Stellite S2 |

| 250°C 480°F | 300°C 570°F |

| Stellite S2 | cobalt-based with high chromium content and additions of tungsten and nickel Can be used in combination with N31 |

| 150°C an depending on material combination | 300°C an depending on material combination |

| N33 | high chromium alloyed stainless steel, additions of nickel, molybdenum and manganese |

| 200°C 392°F | 220°C 428°F |

| N33-4 | high chromium alloyed stainless steel, additions of nickel, molybdenum and manganese |

| 350°C 665°F | 450°C 840°F |

The pump drive connection is available in following types:

- shaft type

- plug type

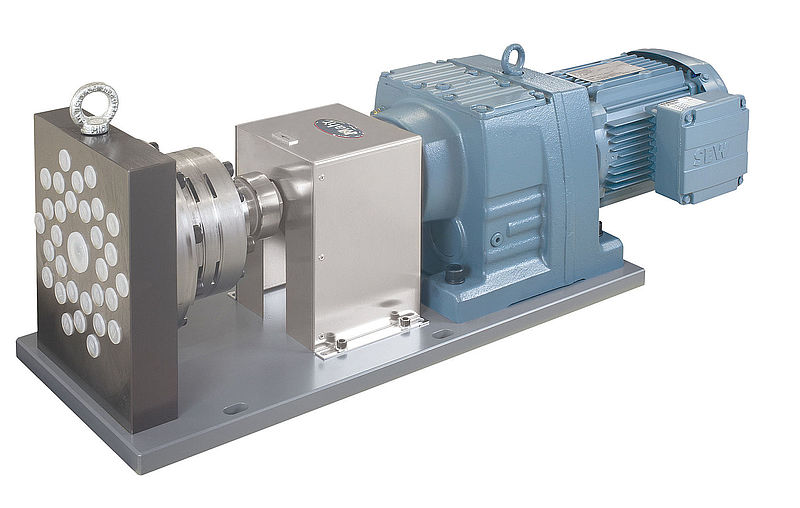

Gear pump with motor

- Base plate with mounting block

- Coupling

- curved tooth coupling

- cardan shafts

- all-steel coupling

- magnetic coupling

- Motor

- asynchronous gear motor

- servomotor / servo gear motor

- synchronous gear motor

The drive units are designed according to the operating conditions.

Coating

Coating technologies take a significant key position in the development of new products. The various coating technologies enlarge the application possibilities of the base materials. Furthermore, a coating reduces friction, wear and corrosion. In principle, all named materials can be coated depending on the specification.

Diamond-Like Carbon (DLC) improves the properties:

- high surface hardness

- high wear protection

- smaller coefficient of friction

- better corrosion reduction to aggressive media

- higher chemical resistance / stability

- non-stick effect (reduced adhesion of polymers and other materials)

- high temperature firmness to 250°C

- excellent accuracy to size (no change of the high discharge accuracies)

- high economic efficiency through longer endurance and improvement of technological properties

- biocompatible, allows the use in the food industry and in the medical field

Sealing systems for the gear pumps

- stuffing box seal

- rotary shaft seal

- labyrinth seal

- mechanical seal

- magnetic coupling

Atex Directive 2014/34/EU

A version according to the Atex directive is available for the pump as well as for the drive.

Heating or cooling for the gear pumps Heating or cooling can be provided electrically as well as by the thermal fluid.

Inquiry Specification

Gear Metering Pumps

Please fill out this form – with this data we will select the suitable gear pump.

Inquiry Specification

Drive Unit

Please fill out this form – with this data we will select the suitable drive for the pump.

The entire pump portfolio cannot be completely listed due to the large number of available designs. The same applies to the fields of application. Please contact us!

Do you have questions about our products?

Please contact us at +49 (0) 551-7073-100