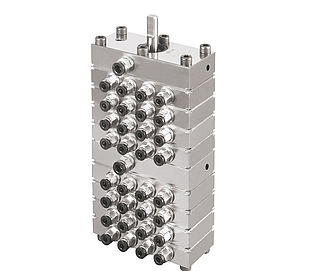

High-quality metrology for quality control in the measuring room, production, incoming goods and development.

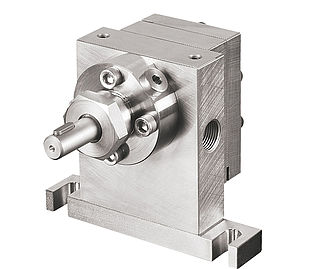

Gear Metering Pumps & Meter Mix Dispense Machines with highest accuracy for processing liquids and pastes.

High-precision rotary stroke bearings for backlash-free linear and rotational movements for use in machine and device construction.

Pioneering machine solutions for the construction industry with high efficiency and advanced technology

Proven use for decades to spin finest yarn: planetary spinning pumps are the heart of every synthetic fibre spinning plant.

Spin finish dosing pumps do not only meter preparation fluids. They can also be used for the consistent dosing of water, perfume or even oils.

There are almost no limits to the use as a dosing pump in various industries. As a spinning pump it is only used for special applications.

Predominantly used in spinning and adhesives technology, they offer the possibility of realizing two flow rates with minimal space and one motor drive only.

Product bores which are on both sides of the pump body allow the pump to be integrated directly into the production line.

They can be used for all applications. Direct installation in the product line does not require an additional clamping block.

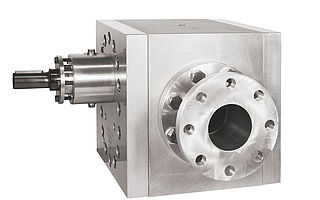

Discharge pumps ensure gentle discharge of polymer melts with low product shear. Booster pumps ensure a defined process pressure for downstream tools such as dies or extruders.

Gear pumps for the chemical industry, process pumps

Optimized metering pumps for chemical processes – low-pulsation gear pumps with high chemical resistance and precise metering

Paint metering pumps can also be used for robot applications. Even at short flushing cycles these pumps show excellent flushing results.

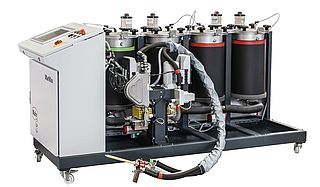

Solutions for material preparation, conditioning and supply to the meter mix dispense machine.

Lightweight design:

2C - 3C Meter Mix Dispense Machine for low flow rates

Our allrounder:

1C - 4C Meter Mix Dispense Machine for low to medium flow rates

Compact and efficient:

2C - 4C Meter Mix Dispense Machine with an output of up to 10 l/min

High-capacity:

2C - nC Meter Mix Dispense Machine for high material flow rates

Customised solutions:

perfectly tailored to suit your application

The mixing takes place exclusively through the flow movement of the components and the geometry of the mixing element.

The components are mixed by a rotating element in a mixing chamber.

The mixing takes place through the flow movement of the components in cooperation with the geometry and rotation of the mixing element.

MarMax CP 30 for low to medium flow rates

1- 4C machine for low to medium flow rates. With an output of up to 6l/min it is suited for all industries. Available designs: 1C, 2C, 1+2C, 1+3C or 2+2C. This provides a high flexibility for processing different material systems suiting your requirements.

The all-round talent

- flexible application

- suitable for a wide range of applications

- individually configurable

- automatic filling possible by connection to IBC, 200L drum or ring line

The Mahr Unipre control software MEC 500 monitors the flow rate, the pressures and temperatures and controls the emission of the components. Warnings are given in simple language for unambiguous understanding, enabling the operator to act quickly. Individual user assignment protects specific parameters against unauthorised changes.

| Emission range | 0.1 - 6 litres/min |

|---|---|

| Mixing ratio | Infinitely variable |

| Material tank sizes | 3 - 60 litres |

| Conveying element | Gear metering pump with stuffing box sealing |

| Remote servicing | Remote service capability integrated |

| Tank filling | Manual |

| Control system | MEC 500 |

| Operation via colour touch screen panel | Screen size 15" |

| Heating | Unheated (optionally heatable up to 85°C) |

| Meter/Mixing Head | Suited to product and process |

- Gear flow meter / screw flow meter / coriolis flow meter / flow meter virtual

- Partially or completely heated up to 85°C

- Gap filter

- Gear metering pump with magnetic coupling

- Other conveying elements on request

- Pressure monitoring on suction side

- Flushing medium container 10 l, 19.5 l or 30 l

- Automatic refilling

Optional connection to 200 l drum, IBC or ring line - Level control of roll bath

- Integration of further systems

- Calculation of layer thickness

- Pot life monitoring

- Quantity counter

- Different application nozzles

- Screen size 21.5"

Suitable for these applications:

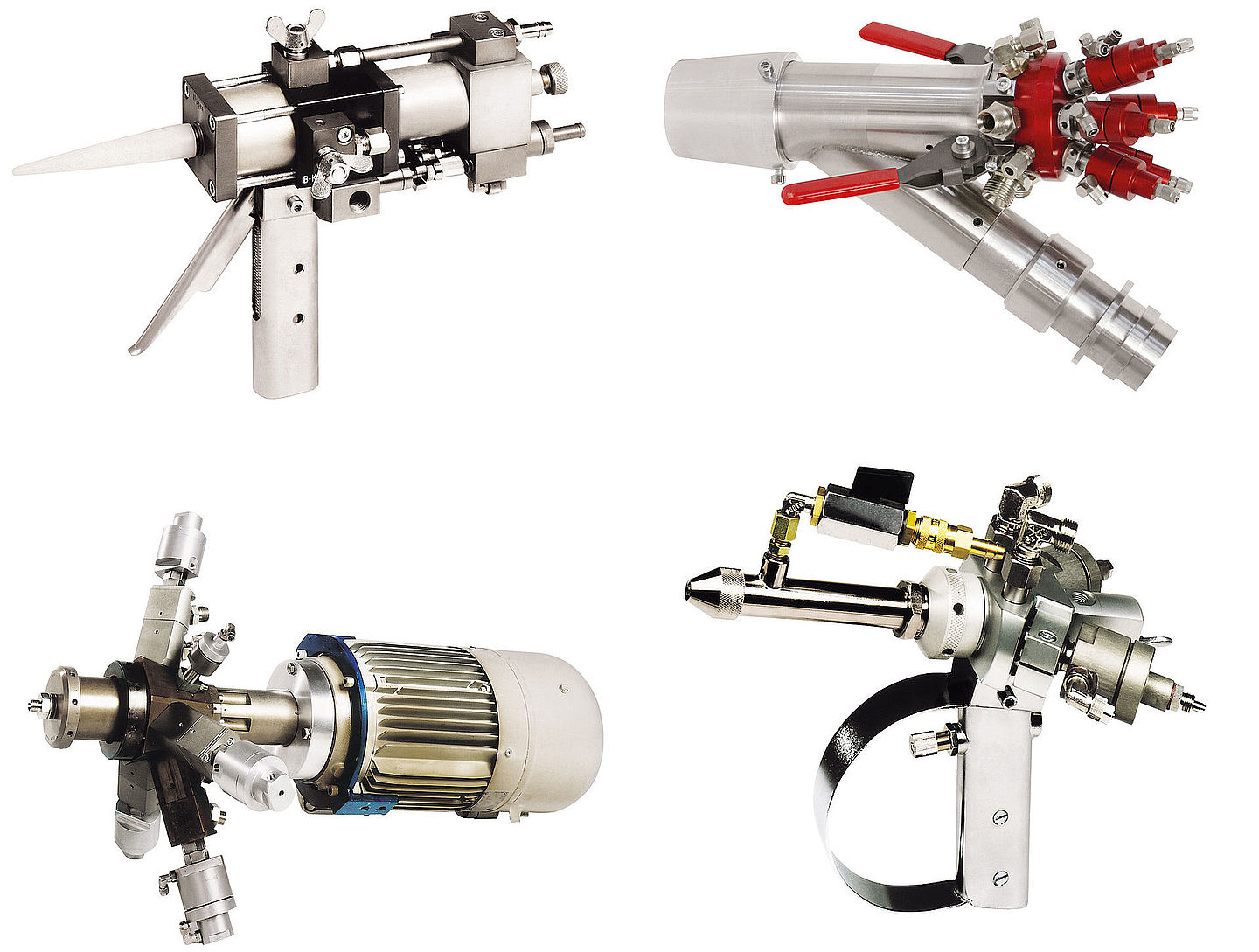

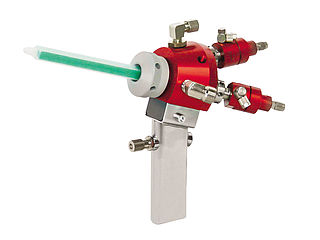

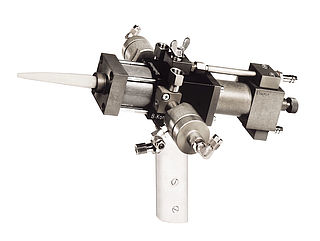

Mixing Heads – the mixture makes the difference

A perfectly customized mixing head guarantees the best mixing quality and exact discharge capacity. In order to select the suitable mixing head, we analyse the production process considering the operating parameters, such as material characteristics, the emission and the mixing ratio.

Mixing Heads – the mixture makes the difference

A perfectly customized mixing head guarantees the best mixing quality and exact discharge capacity. In order to select the suitable mixing head, we analyse the production process considering the operating parameters, such as material characteristics, the emission and the mixing ratio.

Do you have questions about our products?

Please contact us at +49 (0) 2922-87840-0